Pipe Fabrication

slider on services SE

h1 section on service pages

Pipe spools and modular pipe fabrications

HomepageServices 1

Fabrication Shop: Cost-Effective Pipe and Flange Assemblies

Pipe fabrication through prefabricated spools saves money, time, and ensures consistent quality. Prefabrication is a proven method for fast delivery and precise pipe components tailored to project needs. As experienced pipe fabricators, we have successfully collaborated with numerous companies across various industries, delivering high-quality pipe systems and components.

Our customers have high demands, and we never compromise. By consistently delivering quality, we have established ourselves as a trusted pipe fabrication contractor capable of customizing pipe details to meet project-specific requirements. This commitment has made us a sought-after partner, with many returning clients relying on our expertise.

Services 2

The Smart Choice with Prefabricated Pipe Spools

Prefabrication of pipe spools is a cost-effective and time-saving solution for high-quality pipe systems and components. By completing most of the pipe fab work in-house, we ensure that every moment on construction site is used efficiently, reducing delays and increasing productivity. This approach is especially valuable for large-scale piping projects, where precision, timing, and quality are critical to success.

Key Benefits of Pipe Fabrication and Prefabrication:

- ✔ Higher efficiency. Prefabrication allows all on-site time to be focused on assembly rather than welding and adjustments, streamlining the installation process.

- ✔ Superior pipe welding quality. All welding piping components is performed in controlled workshop conditions, minimizing defects and ensuring stronger, more reliable fuses.

- ✔ Timely and fast delivery. With proper planning, prefabricated components arrive ready for installation, improving scheduling and accelerating project completion.

- ✔ Lower costs can be achieved through efficient pipe fabrication processes. Optimized workflows, including pipe cutting and pipe bending, reduce labor and material costs while maintaining high precision.

- ✔Accurate fit-up inspection. Before shipment, every assembly undergoes thorough fit-up inspection to ensure alignment, tolerances, and readiness for field installation.

With extensive experience in pipe fabrication and contracting, we guarantee that every project meets the highest industry standards and design requirements. Our facility is equipped to handle large-scale production and includes equipment designed to handle heavy pipe spools, pipe bending, and complex assemblies. This ensures that your prefabricated pipe systems, including carbon steel components, are delivered efficiently, reliably, and to exact specifications.

Services 3

Experienced Pipe Contractor Specializing in Welded Assemblies and Work to Specification

We look forward to the growing demand for pipe fabrication. By focusing on meticulous preparation and high-quality execution, we can ensure that you benefit as much as possible from pipe fabrication—regardless of size and scope.

With coded welders and welding engineers, all fabrication is performed in accordance with applicable standards. This includes full inspection and testing, along with clear documentation that makes it easy to verify that everything has been done correctly.

By ensuring careful planning, we maximize the benefits that prefabrication can provide. For you, this means getting a high-quality result that costs less than otherwise, thanks to our efficient pipe fabrication process and complete quality control capabilities.

With a strong sense of quality and commitment, we constantly strive to exceed our customers' expectations—no matter your fabrication needs.

Services 4

Certified Prefabrication in Full Compliance with Pipe Fabrication Specification

With a strong focus on quality, we ensure that every step of the pipe fabrication process is completed efficiently, without compromising safety or precision. Our commitment to excellence has made us a trusted partner, always prioritizing our customers' needs.

We are certified according to ISO 3834-2 We follow strict guidelines, guaranteeing compliance with the highest welding quality standards for all pipe fittings. Additionally, we maintain our own library of WPQR (Welding Procedure Qualification Records) and WPS (Welding Procedure Specifications), ensuring that all welding processes meet strict industry requirements.

Why Choose Our Pipe Fabrication Services?

- Optimized efficiency. We perform welding and pipes in advance to streamline installation.

- Experienced professionals. Our skilled team ensures precise planning and high-quality execution, built on decades of experience.

- Certified quality. We operate under ISO 3834-2 certification and follow pre-qualified welding procedures from our WPQR/WPS library for consistent, high-quality results.

- Tailored solutions. We collaborate with you to deliver pipe systems and components, including flanges and fittings, that meet your exact specifications.

- Flexible approach. With high adaptability, we work according to your project requirements and expectations.

- Commitment to quality. Our customers are our most valuable asset, and we never compromise on results.

Pipe fabrication requires technical precision, experienced professionals, and the ability to manage hundreds of components across complex assemblies. We use methods appropriate to fabricate pipe in accordance with the highest standards.

By combining expertise with careful planning and certified welding procedures, we guarantee reliable and efficient pipe fabrication, ensuring your pipeline project runs smoothly and successfully.

Services 5

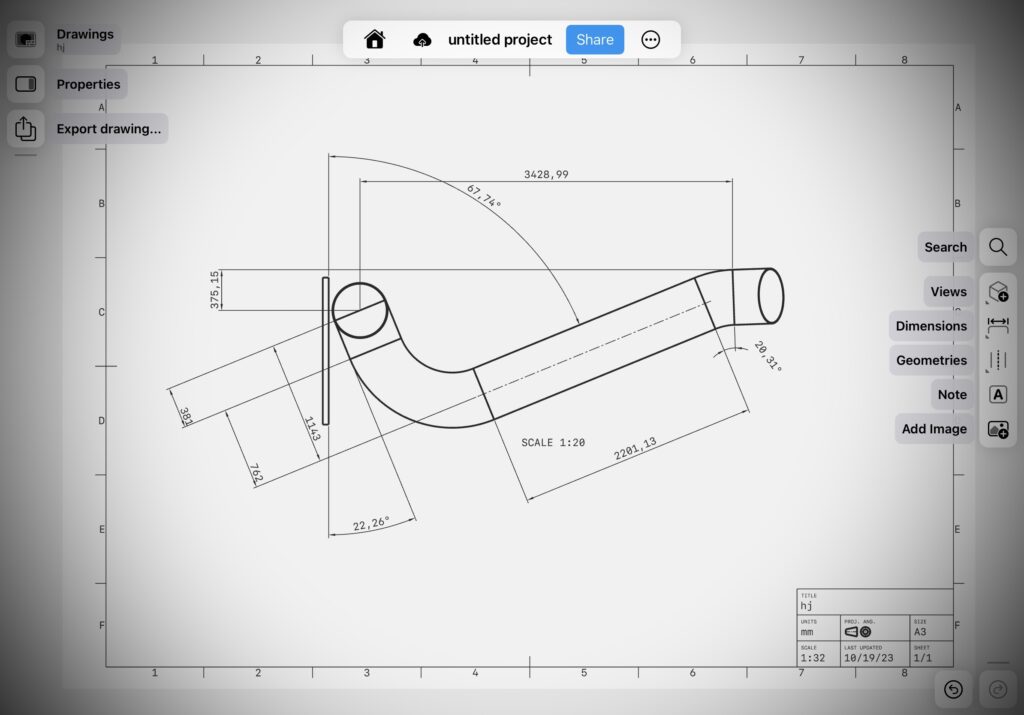

Better results for pipe spools with 3D scanning

By working with optical 3D scanning, we create precise templates for what needs to be manufactured. Our engineers work with AutoCAD and Building Information Modeling (BIM) for the highest possible level of detail and accuracy

- We will be at the project location within three days of your contact

- In consultation with you, we evaluate and make laser measurements

- Based on data collected at the project site, we prefabricate the required pipes and components, and perform testing to ensure quality and compliance

- In the final phase of the project, we install and ensure that everything is done according to your expectations

Using 3D laser scanning is a guarantee that the measurements for your carbon steel components are of the highest possible level. It is a necessity for high-quality prefabrication

Services 6

Wide network for high efficiency

We have a large number of partners to ensure fast pipe section fabrication and timely deliveries. As our Swedish representative, Stinsenman Sverige AB ensures that you always have contact with people who understand the peculiarities of the Swedish market.

Prefabrication is done in collaboration with our Swedish and Estonian partner factories. With strong capacity and skilled personnel availability, they have the right experience and expertise to handle even the most demanding construction projects.

Whether it is prefabrication of pipes and fittings or on-site work, we constantly strive to exceed expectations. Prefabrication allows us to divide a large project into more manageable units, making planning, logistics, and execution more efficient—whether in the shop or on site.

This enables us to deliver exactly the kind of services and components that are in demand. When you choose to collaborate with us, you get a long-term partner who always ensures quality. Contact us for prefabrication of modular pipe systems and components.

We are a pipe contractor who consistently delivers excellent results at favorable prices.

Services 5

Precision and Control in Shop Fabricated Metallic Piping

To meet the most demanding requirements in modern industry, we provide fabrication solutions for industrial piping that combine precision, compliance, and cost-efficiency. All metallic pipe components—whether steel piping, stainless steel pipe, or alloy steel—are shop fabricated under strict quality control procedures using advanced machines and proven methods.

Our production process includes plasma cutting, beveling, saw cutting, and tack welding, followed by careful alignment and inspection, ensuring accuracy and weld readiness according to the scope of the project and the specific piping material. Where required, pipe thread machining is also performed to match system design and installation needs.

We strictly follow all applicable codes and standards, ensuring that every spool number corresponds to the correct component and traceable documentation. Each spool is marked with an aluminum tag, which guarantees full traceability throughout the project lifecycle.

To confirm the integrity of every weld and material, we incorporate non-destructive testing methods to detect possible corrosion or structural defects, ensuring safety and performance before any component reaches the field.

From small custom jobs to large-scale industrial piping systems, our fabrication shop delivers high-quality, code-compliant solutions you can rely on—built to your exact specifications.

section-c98d27b

Our offices

We mostly operate in Sweden, Norway and Denmark but we would love to get involved in a project anywhere in the world.

We also had some very exiting projects in Switzerland, Austria and Malta. There are no limits for us!

19

Years

Of Experience

4

Offices

In Europe

12

Team