Best Drill bit sharpener and Tig tungsten sharpener

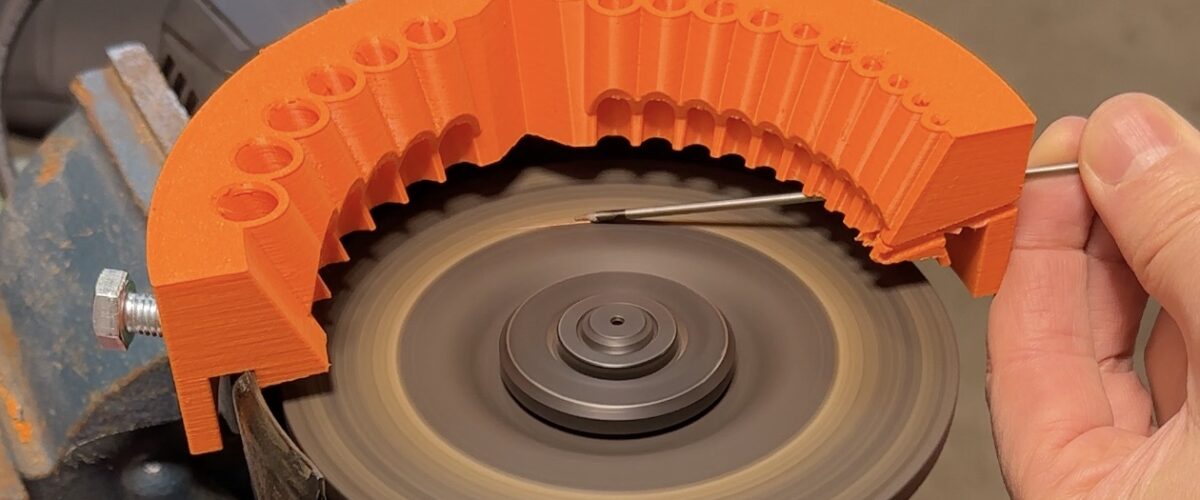

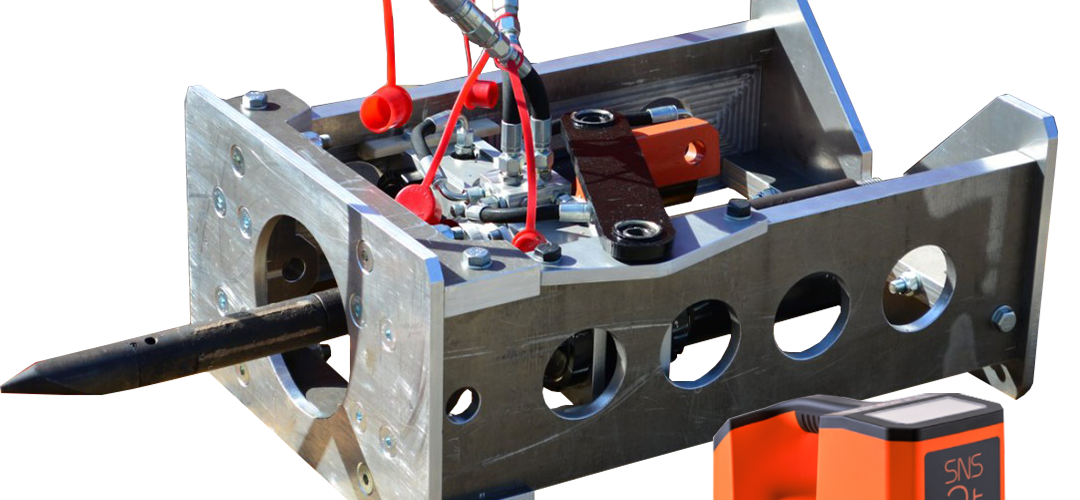

As a CEO committed to innovation and operational excellence, I am proud to introduce our proprietary 3D-printed drill bit sharpener attachment for angle grinders—a tool that redefines the process of sharpening twist drills, carbide, and tungsten for TIG welding. Unlike many market options priced between 3 to 15 euros and often requiring adjustments, our compact design was engineered with precision, versatility, and performance in mind. It’s also considered one of the best overall solutions in its class.

Compact Drill Bit Sharpener Attachment using Any Grinder: Key Features

Universal Compatibility:

Tested on industry-leading brands such as Bosch, Makita, and Milwaukee, our attachment fits most standard angle grinders. It has been engineered to accommodate various protective guard heights (from 15 mm to 26 mm), allowing compatibility with different grinding wheel types and sizes, including options found on a belt grinder.

Precision Sharpening:

Sharpening accuracy is crucial. Our design of the sharpener attachment maintains correct tip angles, enabling you to sharpen everything from standard drill bits to split point and cobalt or HSS types. We also recommend optimal disc types for your specific needs, making it suitable for many types of drill and materials.

Dual Functionality:

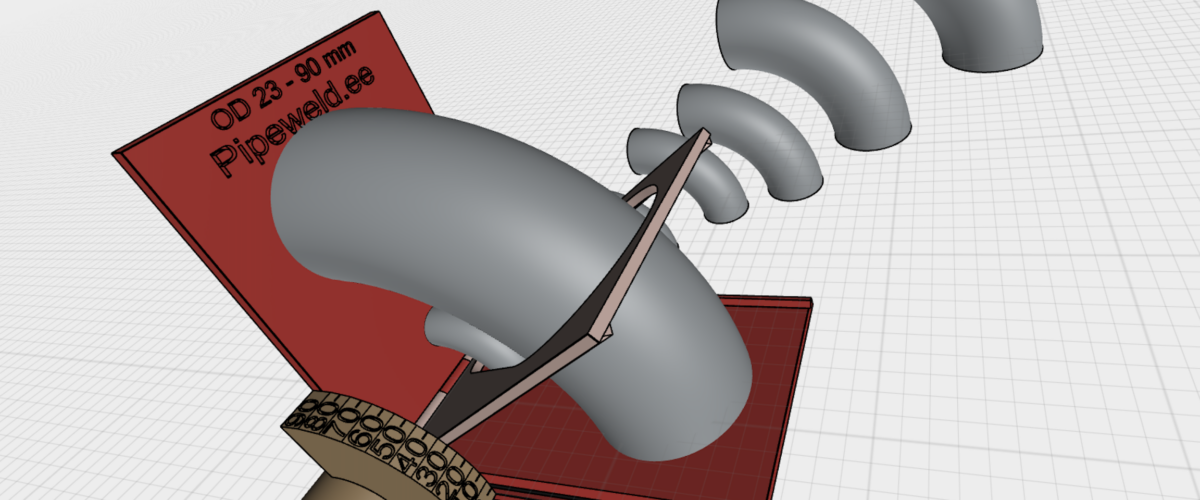

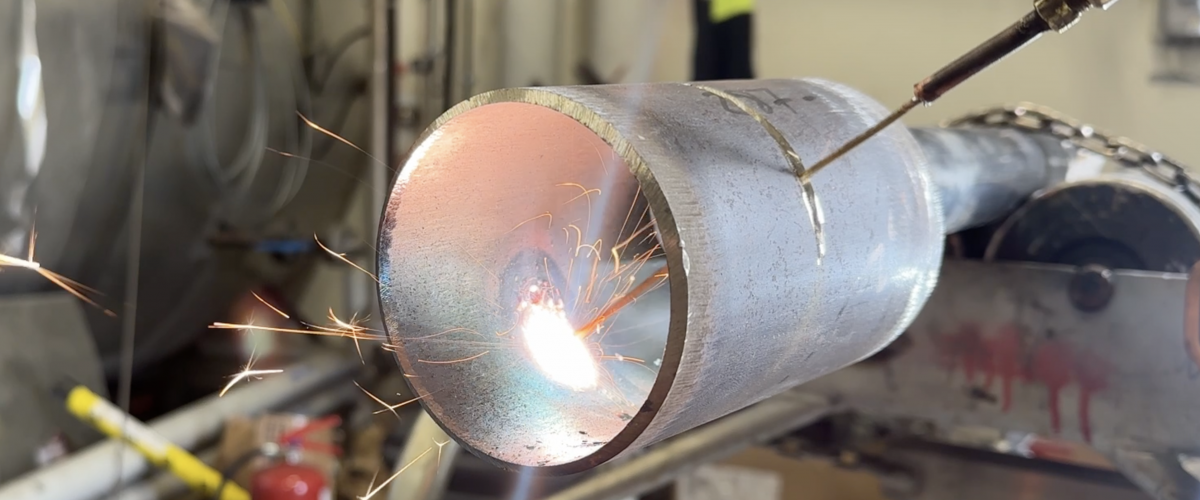

Our attachment not only sharpens dull bits, but also accurately prepares tungsten electrodes for TIG. This portable drill bit sharpener doubles as a TIG tungsten sharpener, making it ideal for machinists, welders, and professional drill users alike.

Portable & Efficient:

Unlike a stationary bench grinder, this grinder drill bit sharpener is portable, compact, and easy to use in any setting. Whether you’re sharpening small bits or preparing tools for heavy-duty jobs, it’s the ideal solution. A great addition to any workshop or portable bits sharpening machine setup.

How to Use the Portable Drill Grinding Attachment

1. Sharpening Dull Drill Bits

- Disc Selection:

While a standard grinding disc can be used, the best results are achieved with a worn grinding wheal that has a pre-processed face. This pre-worn surface provides a smoother, more refined finish—exactly what is needed for sharpening drill bits.

- Cooling:

Due to the high rotational speed of angle grinders, it is essential to periodically cool the drill bit during the sharpening process to maintain optimal performance.

- Sharpening Jig:

The included sharpening jig ensures precision on every pass, even for smaller bits and specialized tips like a point angle adjustable drill bit or split point.

2. Sharpening Tungsten for TIG Welding

- Recommended Discs:

A lamellar or grinding disc is ideal for preparing tungsten electrodes. If these are not available, alternative accessible options may be used effectively.

How to Get Your Free Attachment for sharpening bits

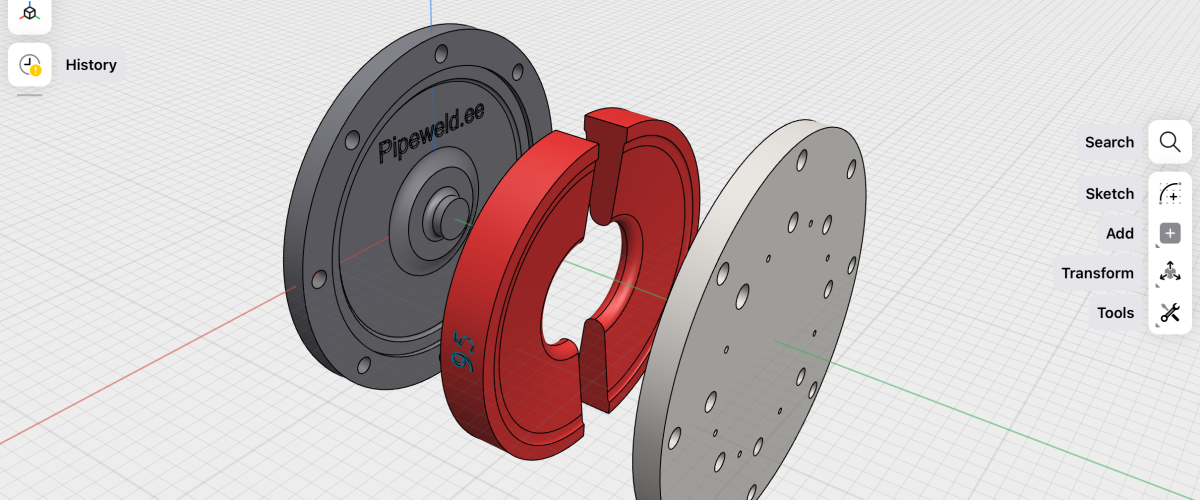

- Download the 3D Model: STL model

- Access the STL file for the design.

- Print on a 3D Printer:

Ensure a fill density of at least 50% for additional rigidity. - Prepare the Component:

- Thread three pre-designed holes (M8) after removing any supports from the print.

- Use three M8 bolts (20–30 mm in length).

- Drill two additional holes for tungsten feed.

*Compatible with many drill bit types, including HSS, cobalt, and carbide—whether you’re sharpening new drill bits or reviving your old drill tools.

Support Our Project

We value your input and invite you to leave a comment with your feedback—even a short note helps us grow and improve. Share this page with fellow tool users, DIYers, and professionals.

Let’s reshape the way people sharpen their bits—from the old drill in the garage to high-speed steel tools in the field.

Ilja Arhi