Industrial pipe project № – 174 completed.

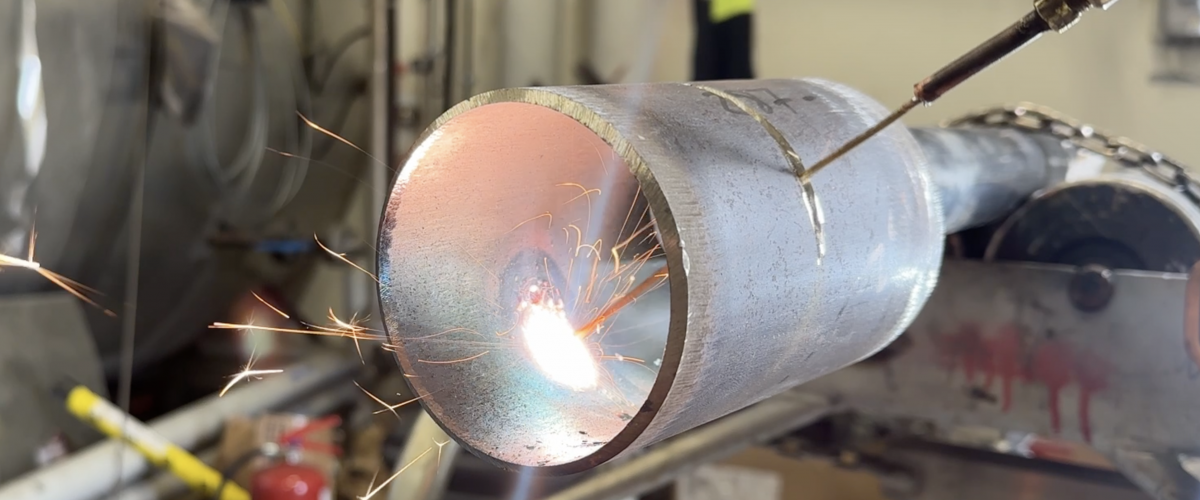

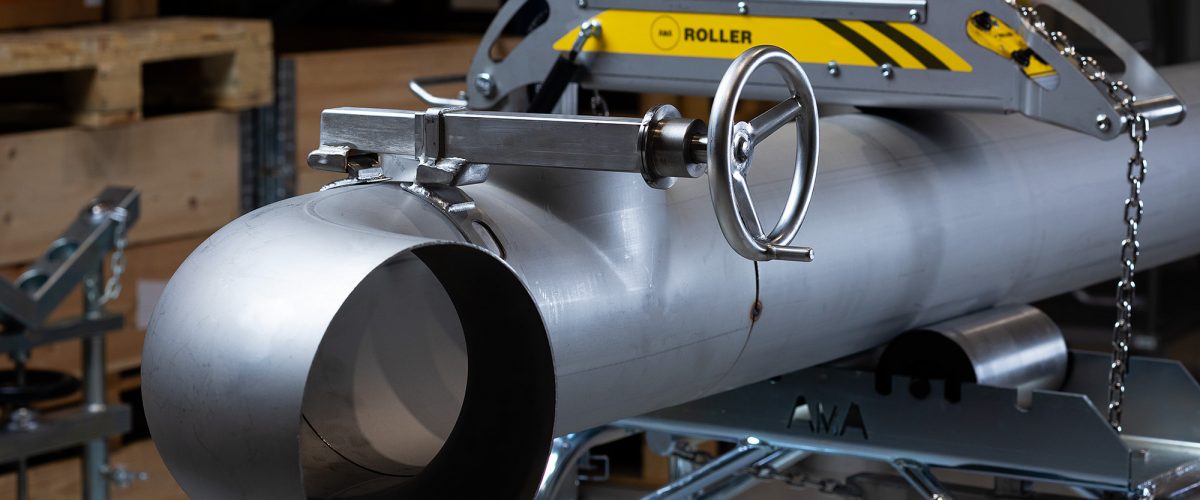

The project involved the installation of a new steam turbine in a power plant, showcasing the complexity and importance of proper planning and organization in large-scale energy projects. Upon receiving a request for assistance with the installation and welding of industrial pipe from the main contractor, Hjalmarssons, PipeWeld.ee quickly mobilized to the job site with all necessary equipment.

Digitalization in Large-Scale Industrial Pipe Projects

The team faced initial challenges in locating and identifying the correct pipe parts, but was able to streamline the process by creating a digital registry of all pipe spools and training subcontractors on its use. This reduced the average time for finding and accessing industrial pipe parts from three hours to just 15 minutes.

With these logistical issues resolved, the team moved on to the welding and installation phase, which went smoothly thanks to their expertise and experience in industrial pipe projects. At the conclusion of the project, the client praised PipeWeld.ee for their efficiency and attention to detail, highlighting the importance of investing in proper planning and organization in power plant projects from the outset.

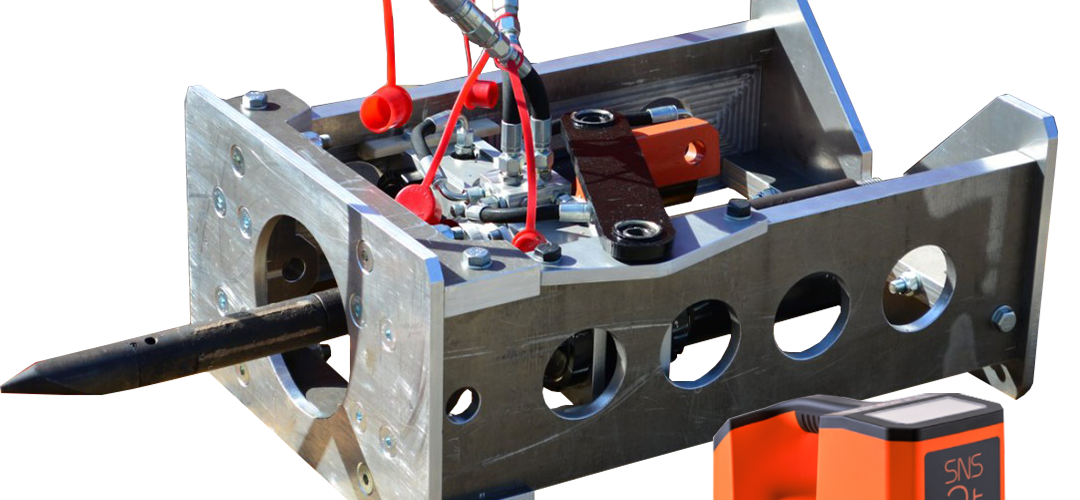

Punch-out process

At the end of the project, PipeWeld.ee was asked to lead the punch-out process, a thorough inspection of all 500 lines already installed to ensure compliance with the project drawings. Although not a complex task, it required a high level of attention to detail and accuracy to ensure that all lines were installed correctly. Our team took on this responsibility with great care, working closely with the client and other contractors to ensure that all lines met project specifications.

Download Punch List for Industrial Pipe Project

This final step was crucial to the power plant project’s success, as it ensured that the plant would operate safely and efficiently. Overall, the project was a great success for PipeWeld.ee, demonstrating the company’s ability to handle large-scale energy projects with a high degree of efficiency and attention to detail in industrial pipe work. The company’s focus on proper planning and organization, along with its expertise in industrial pipe installations, were key factors in the power plant project’s success.

Ilja Arhi – PipeWeld.ee